2016

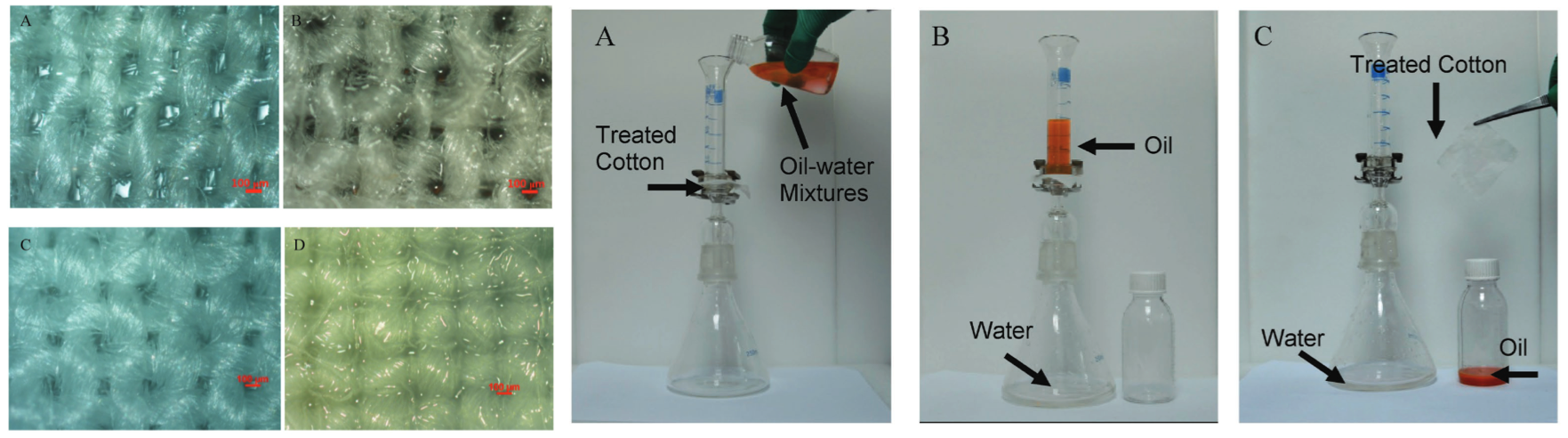

1. Rana M, Chen JT, Yang S, Ma PC*. Biomimetic superoleophobicity of cotton fabrics for efficient oil-water separation. Advanced Materials Interfaces, 2016, 3, 1600128.

■ Hot alkali treatment for natural cotton was used to endow the material underwater oleophobicity, excellent self-cleaning, and antifouling properties. The treated cotton fabrics can successfully separate a wide range of commercial oily products from oil–water mixtures in a gravity-driven filtration operation.

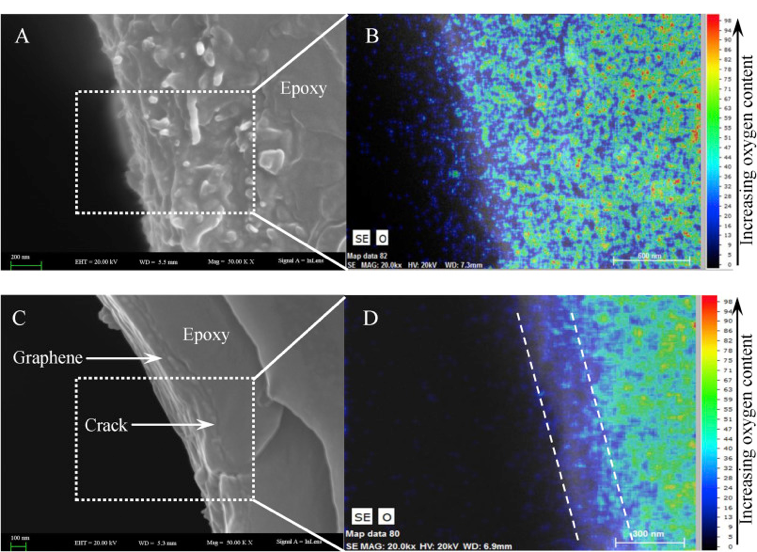

2. Hao B, Ma Q, Yang SD, Mader E, Ma PC*. Comparative study on monitoring structural damage in fiber-reinforced polymers using glass fibers with carbon nanotubes and graphene coating. Composites Science and Technology, 2016, 129, 38-45.

■ CNTs and graphene were successfully deposited on the surface of GFs using an EPD method. Graphene coated GFs showed a higher sensitivity to temperature and mechanical strain than that of CNT samples. The developed GFs were embedded into epoxy to detect failure behavior of corresponding composites. Significant differences on the piezoresistance of samples were observed between CNT-GFRPs and graphene-GFRPs and the resistance change of graphene-GFRPs was more pronounced and detectable than that of CNT-GFRPs under the mechanical loading,

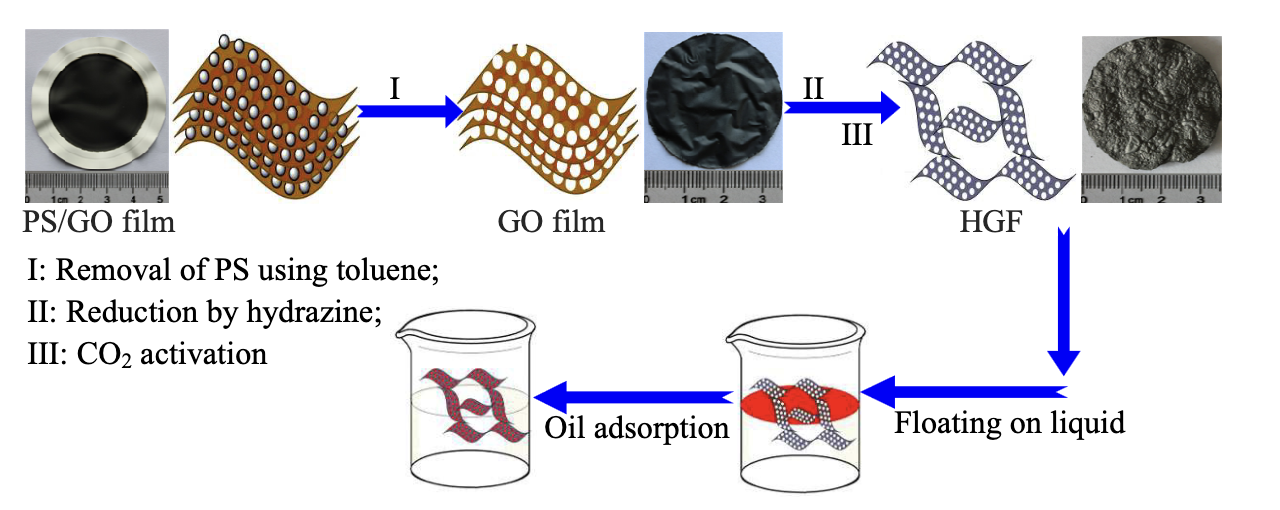

3. Yang SD, Chen L, Mu L, Hao B, Chen JT, Ma PC*. Graphene foam with hierarchical structures for the removal of organic pollutants from water. RSC Advances, 2016, 6, 4889-4898.

■ Three-dimensional graphene foam (GF) was prepared by using polystyrene particles as a sacrificial template and an autoclaved leavening process, and the GF was further processed by carbon dioxide as an activation agent to produce meso- and nano-pores in the foam. The resulting hierarchical graphene foam (HGF) exhibits high porosity, hydrophobicity and excellent thermal stability. Compared to regular GF, HGF manifests outstanding performance for oil adsorption when applied to separating oil–water mixtures.

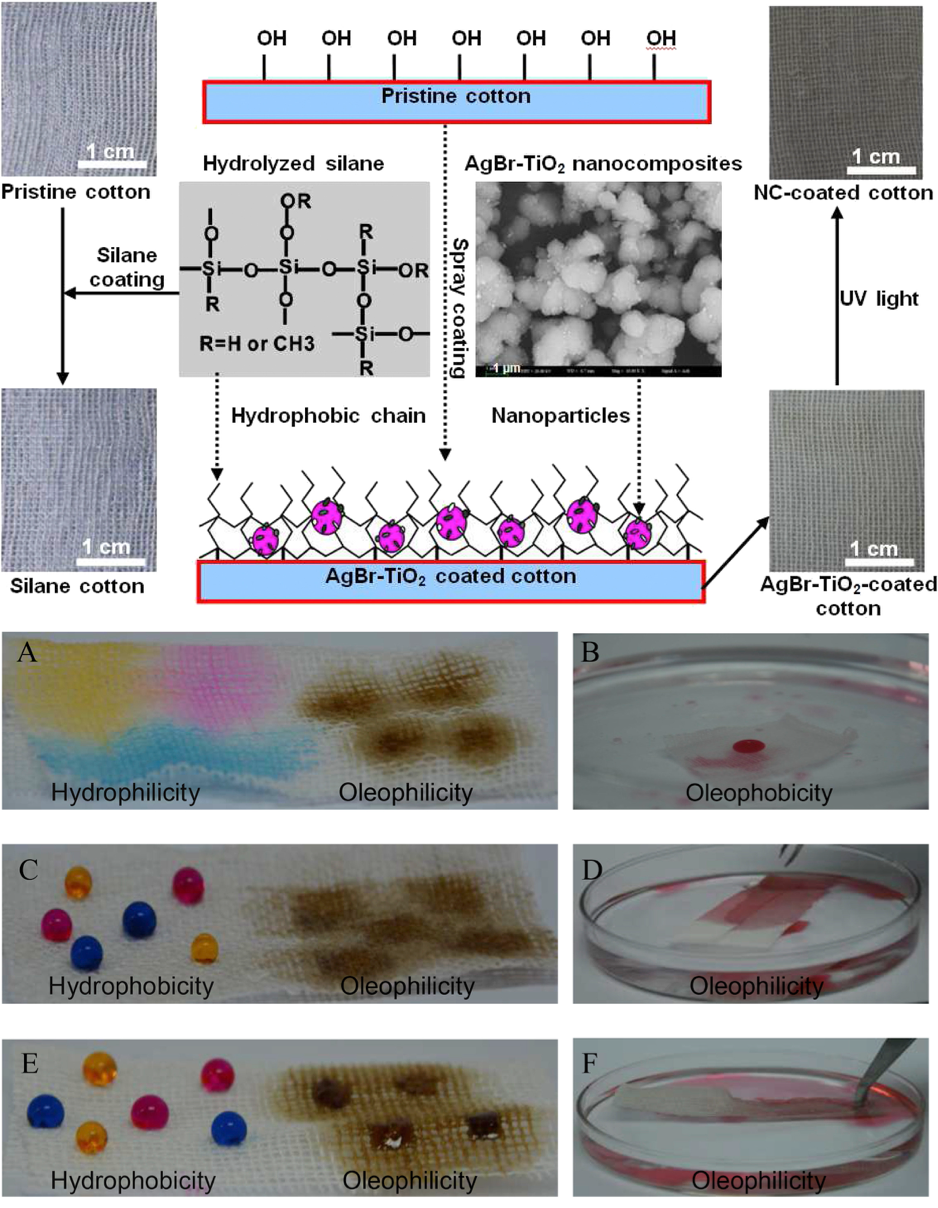

4. Rana M, Hao B, Mu L, Chen L, Ma PC*. Development of multi-functional cotton fabrics with Ag/AgBr-TiO2 nanocomposite coating. Composites Science and Technology, 2016, 122, 104-122.

■ Cotton fabrics with Ag/AgBr–TiO2 nanocomposite coating were prepared by a facile and cost-effective spray coating method. The introduction of nanocomposites onto the fabrics endowed the material multi-functional properties, as verified by the enhanced mechanical properties, controlled wettability to water and oil compounds, and rectified sensitivity to the visible and UV light.

附件下载: